On how to use thermally conductive silicone to solve the LED lamps and lanterns in the heat dissipation problem of small theory

Date:2024-12-28 13:35:36 Hits:1

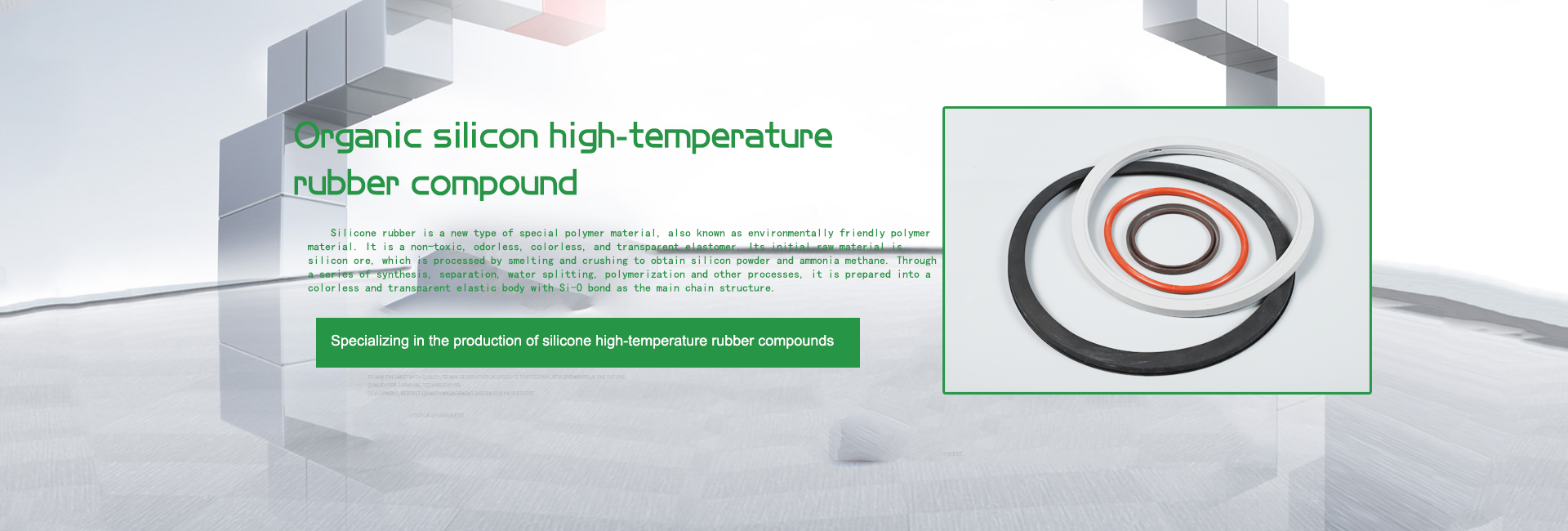

LED silicone is the general name of organic silicone material in LED optoelectronic industry. Due to the epoxy ozone resistance is weak so that the colloid yellowing, affecting the light transmission effect, and silicone material has the resistance to atmospheric aging, ultraviolet aging and other excellent performance, in the application of high-end products epoxy resin has been replaced by LED silicone material.

Method 1, in the LED lamps and lanterns mainly in the aluminum substrate and heat sink between a layer of thermally conductive silica gel, the heat from the aluminum substrate through the thermal conductivity of the silica gel conduction to the heat sink, never to achieve good heat dissipation, to ensure that the heat dissipation effect.

Way two, in the aluminum substrate (PCB board) and LED lighting shell between the addition of thermally conductive silicone sheet.

Way three, between the aluminum substrate and aluminum substrate to add thermal conductive silicone film.

Heat dissipation is the LED lights to focus on solving the problem, and before that the thermal conductivity process is a key. The traditional heat dissipation mode used in the thermal conductive material is thermally conductive silicone grease, thermally conductive silicone grease in the cost will be economical, but in the need for a large area coated, there is a big problem, can not be coated evenly.

Thermally conductive silicone sheet design advantages:

1, insulation: thermally conductive silicone sheet insulation is good, the thickness of 1mm thermally conductive silicone sheet breakdown voltage in more than 8KV, applied to LED in 0.3mm thickness breakdown voltage up to 4KV or more. Thermally conductive silicone grease, although its own insulation is good, but because of the thickness of its coating is extremely thin, resulting in heat-generating equipment and heat sinks near direct contact, so the application, its insulation is not as good as thermal conductive silicone film.

2, use: thermal conductive silicone film size can be arbitrarily cut, both sides of the micro-adhesive, operable, as long as the tear off the protective film directly affixed to the use can be, small tolerances, clean, save labor costs.

3, aging resistance: thermally conductive silicone sheet for the solid form, compared with thermally conductive silicone grease silicone oil is difficult to evaporate, good aging resistance.

4, form: thermally conductive silicone grease for the gel paste, soft thermally conductive silicone sheet pad for the sheet.

5, thickness: as a gap-filling thermal conductive materials, thermal conductive silicone grease is limited, soft thermal conductive silicone pad thickness from 0.3-10mm, a wider range of applications.

6, anti-vibration: thermally conductive silicone sheet for direct insertion of LED, there are pins, if you use the thermal conductive silicone sheet with glass fiber cloth series of products with soft material, compression is good, is the ideal gap-filling material, you can play the effect of anti-vibration in the transportation process.

7, reinstallation: thermally conductive silicone sheet has a slight adhesive, reusable, easy to reinstall. And thermal conductive silicone grease is sticky, not convenient to disassemble and reinstall.

At present, LED thermally conductive silicone is widely used in high-power LED lamps and lanterns, such as: LED fluorescent lamps, LED street lamps, spotlights, floodlights, tunnel lamps, buried lights, wall-washing lights, dye vision lamps and so on.

Typical applications

● LED lighting video equipment

● Backlight module network products

● Switching power supply household appliances

● Medical equipment PC server/workstation

● Communication Equipment Optical Drive/COMBO

● LED TV base station

● Mobile Devices

Click to enquire

Click to enquire